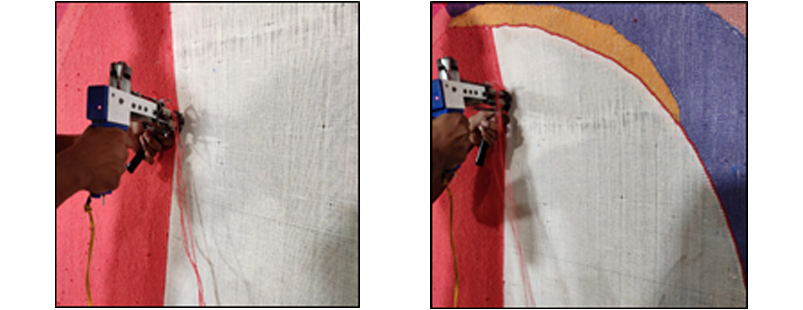

RAW-MATERIAL

Raw Material Selection is one of the key part in the whole rug making process. The sheen and the feel of the finished rug highly depends on the way these raw materials are selected, spun, dyed and washed. These are also known as also known as a feedstock. Most commonly used materials in hand knotted rugs are wool and silk.

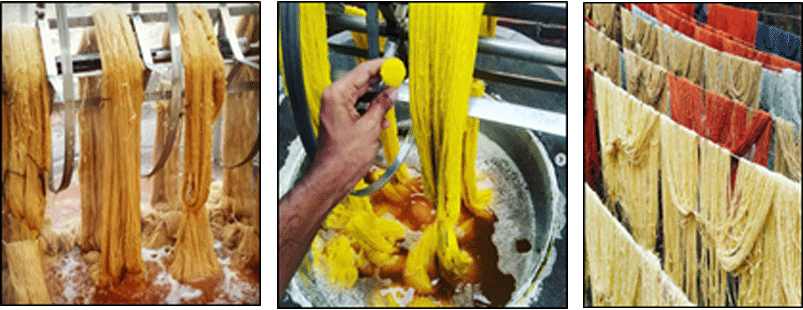

DYING OF WOOL

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. We are capable to do all kinds of Dying and have our own Dying Plant. Different dyes used by us includes all kind of Natural Dye, Herbal Dyes, EZO Free Dyes, Chemical Dyes as per the need of Client/Importers

Depending on the weather, the dyed yarn has to be dried in the sunlight for one to three days.